General Information:

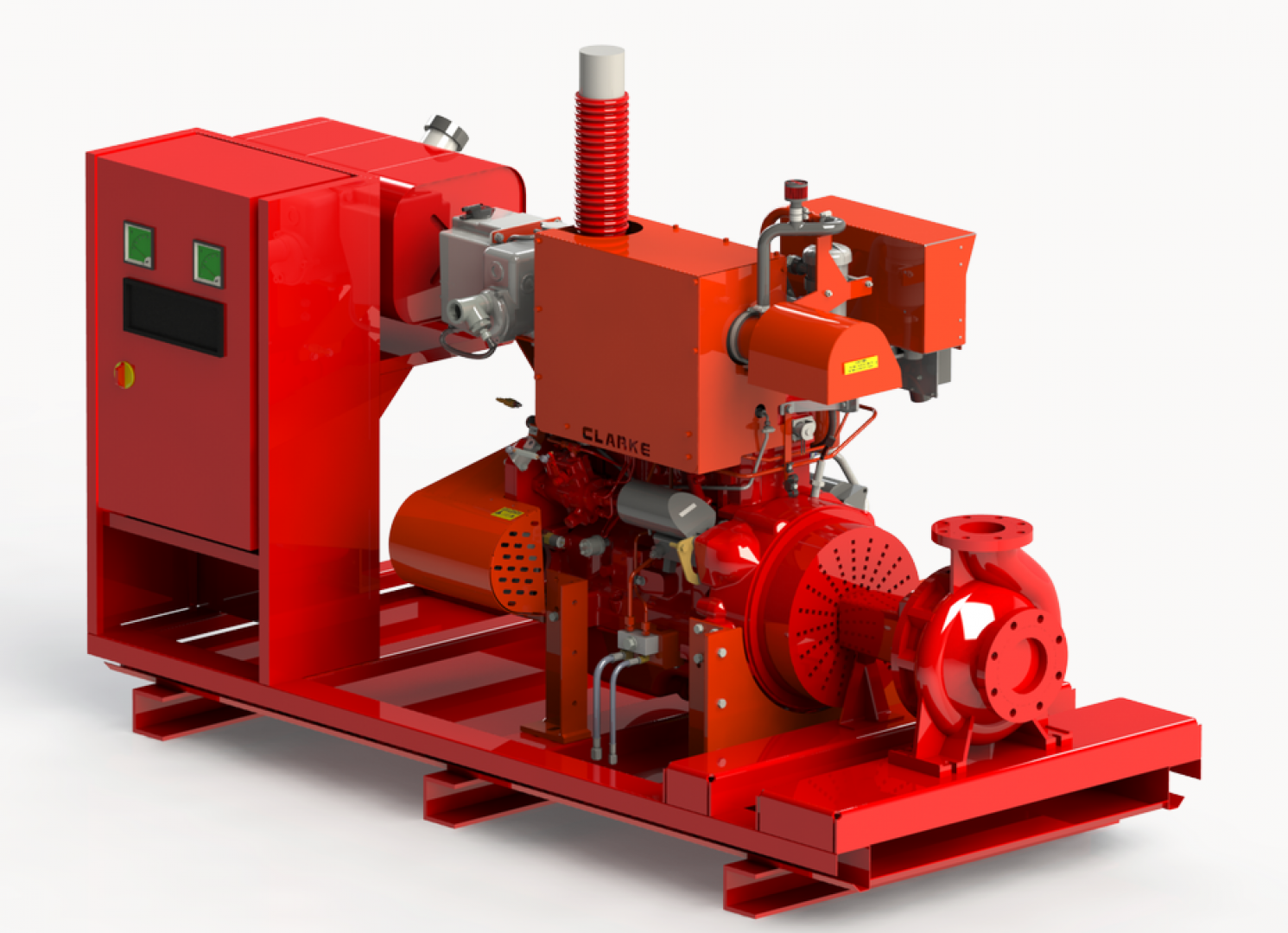

Pumps in the fire group are used for pressurizing fire cabinet, fire hydrant and sprinkler systems. Fire pumps are selected in accordance with NFPA-20 performance criteria and can be designed according to location conditions. The pump type used in the groups are horizontal shaft, end-suction pumps.

The main pumps (diesel and / or electric motor driven) back up each other 100% and in case of failure of the main pump, the backup pump is automatically activated. The purpose of using the jockey pump is to save energy by preventing the main pump, which will provide more capacity than necessary, in case of small flow needs and leakages in the installation. The jockey pump capacity should be less than the feeding capacity of one sprinkler in the system.

There is a separate control panel for each pump.

Structural Features of Main Pump:

Pump Body: GG-25 Cast Iron

Pump Impeller: Bronze

Pump Shaft: Stainless Steel

Sealing: Soft Seal

Bearing: Bearing

Main Pump Features:

They are non-self-priming, axial suction, radial discharge orifice and horizontal shaft single-stage centrifugal pumps. Suction and discharge flanges are according to EN 1092-2 PN10 or PN16. All pumps are dynamically balanced according to ISO 1940 class 6.3, additionally the impellers are balanced hydraulically.

The electric motor is fully enclosed, fan-cooled, squirrel-cage type and complies with IEC and DIN standards. The main pump has a diesel engine driven option.

Hydro Fire Control Panels

Electric Motor Pump Automatic Control Panel:

Electrostatic powder coated polyurethane RAL 3000 color, IP55 protection class.

Panels are locked type.

There is a locked button on the panel that prevents it from staying in the manual position for safety.

Pumps can be operated both manually and automatically.

Main pumps do not have thermal protection. There will be thermal protection on the board of the jockey pump.

The main pumps are designed to be stopped manually for safety when they run automatically.

Pump is running, phase and lack of supply dry contact information can be obtained.

Diesel Driven Pump Automatic Control Panel:

It is electrostatic powder painted, RAL 3000 color, IP55 protection class and locked type.

There is a locked button on the panel that prevents it from staying in manual position for safety.

There is an emergency button to enable the pump to be started for emergencies without any conditions.

There is a liquid crystal display showing the status of the diesel driver on the panel.

Panel diesel engine has the feature of starting six times at intervals that can be adjusted from both batteries.

When the voltage in any battery drops below 9 volts, the other battery is switched to and charging begins.

On the board; General alarm, belt-pulley failure, low oil level, high temperature alarm, A or B battery charge and filling failure information can be obtained.

Low fuel alarm (also displayed in%), pump running, pump ready, mains power available information can be obtained. In addition to these features, general fault dry-contact information can be obtained.